| Sunday, 06 Jul 2025 | | | | | | |

General Electric has revealed details of a new podded thruster developed for vessels servicing the offshore industry

Updated at 12 Apr 2012, 10:01

General Electric’s (GE) Power Conversion business has announced the development of a new propulsion technology intended for offshore support vessels.

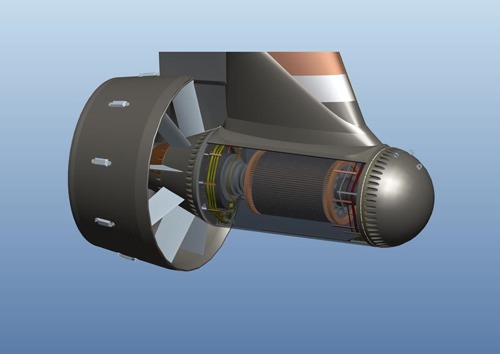

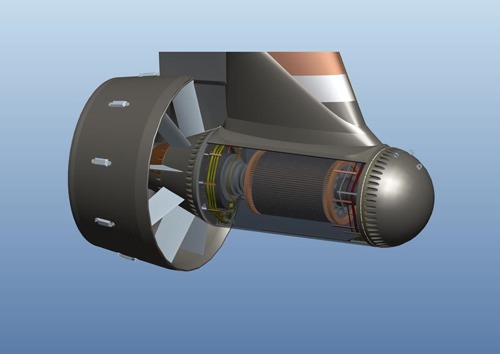

The technology, called Inovelis, incorporates an electrically powered propeller with a motor housed within a steerable pod mounted beneath the vessel’s hull.

GE says that the compactness of the unit also enables an even greater degree of integration between the hull and propulsion unit, which can further influence a vessel’s fuel economy and emissions.

GE says that the compactness of the unit also enables an even greater degree of integration between the hull and propulsion unit, which can further influence a vessel’s fuel economy and emissions.

In addition, Inovelis is said to have higher thrust capability than a more conventional propulsion system, as well as improved hydrodynamics, providing higher efficiency over a wider range of operations, in dynamic positioning (DP) and in transit.

Paul English, marine leader of GE Power Conversion, said: “Inovelis advantage is so significant that it has the potential to permit ship designers to incorporate reduced capacity power plant—fewer cylinders or smaller engines—when designing offshore vessels.”

GE says that the propulsion system is also designed to best suit the performance and fuel efficiency needs of the two standard modes of offshore vessel operation – transit and DP.

English added: “There is a clear trend towards larger, more capable offshore support vessels and a second trend towards the search for oil and gas taking these vessels ever further from home ports.

“Ship operators are looking for systems that support cost-effective, fuel-efficient, rapid transit without sacrificing the capability to operate effectively and efficiently once on site in DP mode. This raises a dilemma as many current designs are a compromise between these two differing requirements.”

GE already has received a number of orders all destined for large PSVs. The first is scheduled for delivery in the second quarter of this year, with ship commissioning around the end of the year.

The propulsion system is based on pump jet principles and features fixed stator vanes and a nozzle that act together to guide the water flow across the impeller blades, which is said to substantially enhance propulsion efficiency. Pump jet technology was originally used in submarines and is already used for high-speed surface vessels.

In addition, Inovelis is said to have higher thrust capability than a more conventional propulsion system, as well as improved hydrodynamics, providing higher efficiency over a wider range of operations, in dynamic positioning (DP) and in transit.

Paul English, marine leader of GE Power Conversion, said: “Inovelis advantage is so significant that it has the potential to permit ship designers to incorporate reduced capacity power plant—fewer cylinders or smaller engines—when designing offshore vessels.”

GE says that the propulsion system is also designed to best suit the performance and fuel efficiency needs of the two standard modes of offshore vessel operation – transit and DP.

English added: “There is a clear trend towards larger, more capable offshore support vessels and a second trend towards the search for oil and gas taking these vessels ever further from home ports.

“Ship operators are looking for systems that support cost-effective, fuel-efficient, rapid transit without sacrificing the capability to operate effectively and efficiently once on site in DP mode. This raises a dilemma as many current designs are a compromise between these two differing requirements.”

GE already has received a number of orders all destined for large PSVs. The first is scheduled for delivery in the second quarter of this year, with ship commissioning around the end of the year.

| MAJOR PROJECTS |   |

| Long | Lmax | = | 31.76 | m |

| Width | B | = | 10.30 | m |

| Hight | H | = | 5.00 | m |

Launching ceremony of PSV 3300